Safety in electric car accidents

Seguridad en accidentes de coches eléctricos

Dr. Pablo Zapico Gutiérrez (1), José Alonso de Linaje Aguirre (2) , José Alejandro Alonso de Linaje Díez (3), Ángel Carlos Rodríguez Llamas (4) , María Zapico Gómez-Collantes (5)

Abstract

Engine vehicle accidents are an undesirable but existing part of mobility, which cannot be completely eliminated. However, the proliferation of electric and hybrid vehicles causes some peculiarities that differentiate them from traditional assumptions.

Keywords: BEV, PHEV/HEV, electric car, safety, accident, electrocution.

Resumen

Los accidentes en vehículos de motor son una parte indeseada pero existente de la movilidad y que no se puede eliminar totalmente. Sin embargo, la proliferación de vehículos eléctricos e híbridos hace que se presenten unas particularidades que los diferencian de los supuestos tradicionales.

Palabras clave: BEV, PHEV/HEV, coche eléctrico, seguridad, accidente, electrocución.

Recibido / received: 18/01/2022 . Aceptado / accepted: 03/01/2023

1 Dpto. de Ingeniería Eléctrica y de Sistemas y Automática.

2 Laboratorio Regional de Combustibles, Junta de Castilla y León.

3 Ayuntamiento de León.

4 I-DE Redes I. S.A.U..

5 PREPA INP Bordeaux.

Autor para correspondencia (corresponding author): Pablo Zapico Gutiérrez, e-mail: pablo.zapico@unileon.es

Introduction and objecctive

As battery electric vehicles (BEV), plug-in hybrid electric vehicles (PHEV) and hybrid electric vehicle (HEV) become more common on our roads and cities, they are also included in accident statistics like any other car. However, they have certain characteristics that make them different from traditional vehicles. In this work, we will try to expose these singularities.

Background

Currently, there are well-proven protocols to deal with accidents in traditional internal combustion engine (ICE) vehicles and they are well-known for their safety. However, such protocols are not yet in place for BEV, PHEV or HEV cars. This is a new use of technology that presents multiple particularities and risks different from those known to date in the automotive industry.

Risks of intervention

The first and most important thing is to identify the accident vehicle/s as BEV, PHEV or HEV through the external indicators used by manufacturers. Each one has its own one and they may have been detached in the crash. Besides, they are not uniform among different brands and require some experience to identify them.

In the market there are PHEV or HEV with an internal combustion engine, and the BEV. The first ones make noise when the conventional engine is started; the second ones do not (this does not mean that they are not under voltage). The PHEV or HEV has an exhaust pipe, the BEV does not, but there are now electric cars with a diesel tank and a small heating boiler. As the battery is not used to heat the cabin, they have a greater range and an exhaust pipe that can be misleading.

Both will have two charging connectors, one for standard on-board charging and the other one for fast charging. HEV will not have any external connector, they are not plug-in, but they have a traction battery. They can be confused with ICE cars, with the corresponding electrocution risk, chemical risk, and so on.

At the time of approaching the accident, the protocol is similar to a conventional accident. However, they have a battery at a voltage of between 200 and 800 volts (400 volts on average) in direct current that makes them different.

Generalities

The first problem that arises is that as it is a new technology and, therefore, there is not enough standardization. The vehicle must be identified as ICE vehicle or PHEV/HEV (they usually have an external identification plate, but it may also have fallen or can be hidden). Then, if possible, check if it is operating, or prepared to do so, in electric mode. The rescue card (usually at the driver’s sun visor, but not all carry it) must be sought. It is important to put the gear lever in the ”parking” (P) position or, at least, in neutral (N) position.

If you can access the dashboard, check if the word ”READY” appears. It indicates that the vehicle is in drive mode (under voltage). Next step is pressing the START/STOP button and moving away the key or radio frequency card at least five meters. Other brands replace the ”READY” sign with a green light pilot on the dashboard or an ”ON”. There is no unique methodology among all manufacturers.

Mechanical risk It is necessary to put the parking brake on, even if it is electric, if it is activated it gets locked, even if the 12-volt battery is disconnected. Then, you have to remove the ignition key and move it away more than five meters. If the battery is disconnected and the parking brake is electric, it will not be able to be activated again. If it is locked like this, it will remain so, but if it is unlocked, it will no longer be able to be used again.

Electric risk

Regarding the voltages used in the traction battery, it should be noted that the Spanish electrical regulation, which is similar to the European one in the Article 2.1 of Royal Decree 337/2014, of May 9, approving the Regulation on technical conditions and safety guarantees in high voltage electrical installations and its Complementary Technical Instructions ITC-RAT 01 to 23, entitled ”Scope of application”, states:

”The provisions of this regulation apply to high-voltage electrical installations, understood as those of three-phase alternating current of service frequency below 100Hz, whose nominal effective voltage between phases is greater than 1kV.”

Article 2.1 of Royal Decree 842/2002, of August 2, approving the Low Voltage Electrotechnical Regulation, entitled ”Scope of application,” says:

”This Regulation shall apply to installations that distribute electrical energy, to electricity generating plants for own consumption and to recipients, within the following limits of nominal voltages:

a) Alternating current: equal to or less than 1,000 volts.

b) Direct current: equal to or less than 1,500 volts.” I

t is clear from all of this that the term ”high voltage” used for the traction battery does not comply with current legislation. However, it does not mean the battery and its working voltage are not dangerous, especially in the case of an accident.

According to Royal Decree 842/2002, of August 2nd, which approves the Low Voltage Electrotechnical Regulation, safety voltages in Spain are 24 volts in damp or wet environments and 50 volts in all other cases, very similar to those established by countries in our environment.

It is evident that the 12-volt battery does not present a risk of death by electrocution. In lead-acid sulfuric acid batteries, the lead sulphate deposits on their terminals are poisonous. It is toxic and corrosive by inhalation, ingestion, and contact. Besides, lead is a cumulative poison and continuous exposure to small amounts can increase the body’s content to toxic levels. Moreover, in the case of a short circuit, it can produce dangerous sparks and projections of melted metal particles. Regarding the traction battery, the criteria is very different. The average voltage is 400 volts and there are some that reach 800 volts. As already seen, it is not high voltage, because according to the regulation cited, it is not considered as such; however it is dangerous.

Almost all manufacturers use orangecolored conductors between the battery and the inverter. This circuit is insulated from the vehicle’s chassis. If the car needs to be lifted, special care must be taken not to place supports under the power cables, as they can be damaged and cause leakage and/or short circuits. There are specific points under the cars to support jacks or lifts.

Normally, when there is a collision involving hybrid or electric vehicles and the airbag sensors are activated, the following safety actions are automatically triggered:

– The hybrid or electric system stops:

• When the impact sensors send signals to the Supplemental Restraint System (SRS) electronic control unit or to the Battery Management System (BMS) or a detection of an electrical imbalance.

• Each time there is an airbag deployment or an electrical imbalance that occurs, when some positive or negative relay of the traction battery is disconnected.

– The direct current flow of the high voltage of the traction battery pack is interrupted and remains open as a prevention of electrical energy leakage from the main battery.

– The fuel pump is deactivate (hybrids). The low voltage energy that flows to power the SRS electronic control unit or the airbag serves to cut off the power supply to the hybrid system. Once the SRS is activated, resulting in the deployment of an airbag, the hybrid system then automatically stops and will not start again without a clear external action:

– Check the windshield if it has a sticker that identifies the vehicle with a rescue sheet. If the sticker is not visible, still check if they have a rescue card or similar, for example on the sun visor.

– Do not rely on not hearing noise, as the vehicle may be connected, running in electric mode and working with electrical voltage.

– Disconnect the ignition key, because, for example, if the victim has their foot on the brake pedal, when removing them and releasing pressure from the pedal, the car can move, since it is automatic.

intended for firefighters.

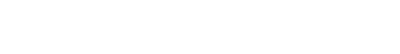

It should be remembered that the inverter that converts the direct current from the battery into threephase alternating current has a series of capacitors that maintain the charge and they discharge slowly after the direct current supply is interrupted. The typical discharge curve of a capacitor is represented in figure 1.

To ensure that these capacitors are discharged, it is advisable to wait at least five minutes from the interruption of the electricity supply. Never cut the power circuit’s ground braids; they are a safety device that serves to protect the occupants of the vehicle and the safety services.

Never cut the orange cables at any point, since they are shielded and when cut with scissors it causes a short circuit, as it connects the active conductor with the shield or ground when cutting.

Normally, by disconnecting the 12-volt battery everything will be out of service and in a safe situation. This is the most recommended solution.

Finally, the existing risks and necessary protective measures are reminded. The use of protections is the only way to avoid injuries caused by the passage of electrical current. The electric arc, if caused, is capable of projecting incandescent metal that can cause serious burns. Therefore, the following safety precautions are recommended:

– Isolate yourself at ground level to avoid the passage of current.

– Insulate your hands with insulated gloves.

– Insulate points near the work area that are in tension or may be so.

– Use insulated and pre-checked tools.

– Use flame-retardant and closed work clothes (even in summer).

– Use a helmet and lowered protective screen (a full-face motorcycle helmet can be an emergency solution).

– Use flame-retardant gloves under insulated gloves.

– You can only dispense with the insulating protections when there are no points in tension within 50 centimetres of the working area (this criterion is only valid for professionals with electrical training).

Chemical safety

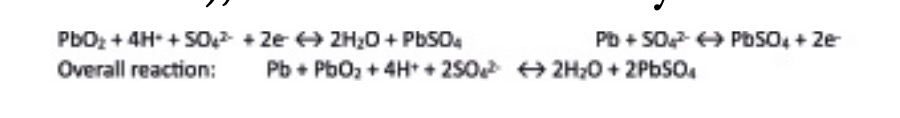

Depending on the manufacturer and type of vehicle, various types of batteries and their variants can be found. We indicate some of them with their corresponding reactions:

– Lead-acid batteries (discharge reactions); sulfuric acid electrolyte

– Ni-Cad batteries; potassium hydroxide electrolyte

– Ni-Cad batteries; potassium hydroxide electrolyte

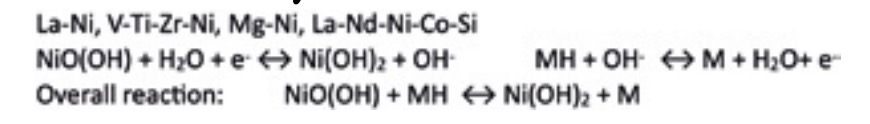

– Ni-metalhydride, NiMH batteries; potassium hydroxide electrolyte; metal hydride anodes of complex stoichiometry, for example:

– Ni-metalhydride, NiMH batteries; potassium hydroxide electrolyte; metal hydride anodes of complex stoichiometry, for example:

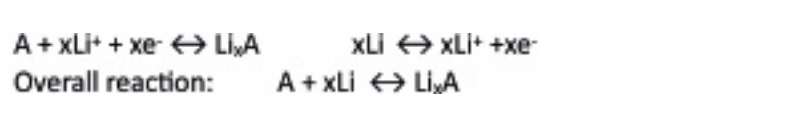

![]() – Lithium-ion batteries: non-aqueous electrolytes (aprotic) or lithium salt due to the thermodynamic instability of lithium; mixed oxides (Co, Ni, Mn, …) or metallic sulphides with Li in cathodes and Li or carbon-Li materials for anodes. Complex reactions depending on the materials used, summarized below:

– Lithium-ion batteries: non-aqueous electrolytes (aprotic) or lithium salt due to the thermodynamic instability of lithium; mixed oxides (Co, Ni, Mn, …) or metallic sulphides with Li in cathodes and Li or carbon-Li materials for anodes. Complex reactions depending on the materials used, summarized below:

oxygen or hydrogen, can be produced.

oxygen or hydrogen, can be produced.

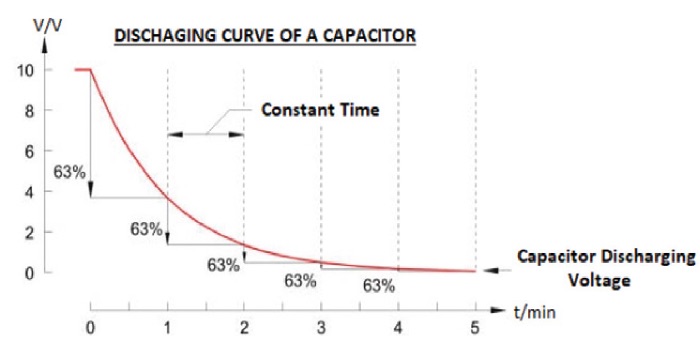

As described, the chemical species that we may encounter will be of variable nature and should be described by the manufacturer and their quantities. Some electrochemical reactions are exothermic in nature and can cause temperature increases in the cells. Pay attention to the safety data sheets for each compound. For example, the NiMH electrolyte is a caustic alkaline substance (pH 13.5) harmful to human tissues, to neutralize a spill of NiMH electrolyte, you could use:

*Litmus paper is one of the oldest acidbase indicators. It is practical, economical and efficient for measuring pH in an approximate way. Neutral litmus paper, in an acidic medium turns red and in a basic medium it turns blue. You can add a drop of the solution to a piece of paper strip or directly submerge a piece of paper strip in the solution. It does not give a quantitative value of the pH but meets the objective of checking if the initial solution (strong base) has been neutralized (Figure 3).

The battery module is wrapped in a metal box, with access only on the top. Never remove the cover, severe electrical burns, discharges, electrocution, release of toxic and/or flammable gases or chemical burns can occur. The electrolyte of the lithium-ion traction battery can be a clear liquid and has a characteristic smell of organic solvent. It is a flammable solution. In case of leakage, it is necessary to ventilate the accident area.

The electrolyte of the battery is corrosive. It causes skin burns and serious eye injuries in case of contact with these parts of the body.

To avoid breathing in the fumes, you must use a self-contained breathing device or a mask with a chemical cartridge. The cartridge will always be replaced whenever it is used, regardless of the duration of use. It is always important to follow the instructions and recommendations of the supplier of the personal protective equipment, in addition to chemical protection gloves and glasses (Figure 4).

In case of ingestion, inhalation, contact with skin or eyes, rinse with plenty of water as soon as possible; call a toxicology information centre and a doctor immediately. In case of inhalation, it should be remembered that the lung is an organ with few defence mechanisms and an instinctive order that compels it to breathe continuously. When it is faced with an unwanted contaminant, the first thing to do is coughing to try to expel it. In case it is already deep and since it is an acid, it is important to try to dilute it, because it can produce lung edema.

If someone has been exposed to an acidic air contaminant, it is best to go, without rush, but on the same day, to the emergency room. There they will treat the victim with an appropriate nebulizer, observe them and, perhaps, administer a diuretic. If the victim goes to bed instead of going to hospital, the situation may worsen due to lack of lung capacity. For fire extinction, water will be used, maintaining safety distances and with a quick and aggressive attack. An offensive fire attack on a battery pack will be carried out by flooding the traction battery pack with large amounts of water. If the fire attack is defensive, it will be carried out at a safe distance, using a jet or a water curtain. ABC or CO2 type fire extinguishers and/ or sand can also be used. After a fire, the vehicle can always pose an electrical risk due to the presence of bare parts under tension and there are still chemical products, so access to the vehicle must be cordoned off.

The main battery is cooled by air in case of fire or overheating. Therefore, the location of the nozzles where air enters is known, and they can be used to introduce water in case of fire or overheating. However, other chemical species may become potentially toxic when in contact with water. In some models, under the backseat, there are hatches that, in case of fire, melt and let water extinguish through them. Insulating footwear will always be used to prevent the entry/exit of current through the feet. Due to the strong heat formation, under certain circumstances, it is important to cool the battery and accept the risk of a lithium chemical reaction with water (in which hydrogen can be produced). In general, and despite some controversies, attempts to extinguish the fire with water in general have positive results.

Car ssumerged in water

In the case of a car submerged in water, the following circumstances occur:

•There is no electrical risk when touching the vehicle and assisting the occupants, after ten minutes of immersion.

•Underwater, the battery will suffer a rapid self-discharge, lowering its voltage.

•The vehicle could still be in “ready”, and the power cables should never be cut or manipulated.

•Stay alert to always avoid skin contact

•with the liquid that comes out of the traction battery.

•If the vehicle is submerged in a closed flooded location (car park, garage), ventilate well the area before intervention.

The safety protocol should be as follows:

1. Remove the vehicle from the water.

2.Empty it completely (if possible).

3. Check: a. If it has a rescue card (usually in the sun visor). b.Put in neutral (N) or parking position (P) (automatic cars). c. Put on the parking brake. d.Remove the key or contact card (and move it +5 meters away).

4.Locate and disconnect the 12 V battery.

5. Locate and remove the power battery service connector.

Note: (if possible) Fill the traction battery with deionized water through the cooling duct, and remove the vehicle to an outdoor ventilated area (for about 72 hours) to avoid the risk of fire, as filling it with deionized water can produce hydrogen generated by electrolysis. It is reminded that the air-hydrogen mixture is flammable and sometimes explosive, although still unconfirmed.

Towing

The first thing to do is to verify which is its drive axle, and that it does not touch the ground. If not, it could cause a fire due to a short circuit produced by the electricity generated by the electric motor. When turning the drive wheels on the asphalt and moving it, it becomes an electric generator. If it has 4 engines, one on each wheel, or two, one on each axle, it is inevitably necessary to transport it on a platform crane.

In an emergency, it is possible to use a cable to tow short distances and at low speed. In general, and in case of doubt, the vehicle will be evacuated from the accident site to the workshop or scrap yard on a platform crane.

Conclusions

In the event of an accident or fire in an electric or hybrid vehicle, these are some of the recommendations that should be considered regarding the new risks generated:

– To limit the electrical risk of the traction battery, it is essential to disconnect the 12-volt battery.

– Avoid any contact with damaged or porous cables, or better, with cables at all.

– It should always be assumed that the traction battery and its associated components are fully charged – Exposed electrical components, cables or traction batteries pose a very dangerous risk of electric shock.

– If the automatic disconnection of the battery has not been carried out, proceed to disconnect it manually

– You cannot rely on the colour of the identification of the cables if you are not sure that the battery is completely disconnected.

– Do not handle without safety gloves protecting above 1,000 volts, boots, and dielectric screen any detached battery element from the vehicle or inside of it.

– The vapers of the traction batteries can be potentially toxic and flammable.

– The damages caused, both in the vehicle and in the power battery, can cause the immediate or delayed release of toxic and/or flammable gases and fire. From the above, it is concluded that the vehicle:

– Must be identified unequivocally as electric or hybrid through an international sign.

– Must have a clear identification of the elements subjected to high tensions

– Has to be equipped with an automatic disconnection device of the battery and/ or its modules and have an easily visible signalling system that guarantees the disconnection has been carried out.

– Information about the chemical components of the batteries and their corresponding safety sheets are available.

– Be equipped with an accessible and redundant manual disconnection system, in the event of failure of the automatic system.

– Be equipped with an overheating detection system for the battery, which warns and, if necessary, acts on the automatic disconnection.

– All of this will result in greater safety for the occupants, the police and security services that have to intervene and the possible public that witnesses the accident.

Bibliografphy

Álvarez Pelegry, E., & Menéndez Sánchez, J. (2017). Energías alternativas para el transporte de pasajeros.

Amsterdam Roundtable Foundation. (2014). Electric vehicles in Europe: gearing up for a new phase? Amsterdam.

Assum, T., Kolbenstvedt, M., & Figenbaum, E. (2014). The future of electromobility in Norway.

BASREC. (2015). The development of electric transport – its effect on the security of the electrical energy system and forecasting energy demand in chosen 8 BASREC countries (Norway, Denmark, Germany, Sweden, Finland, Estonia, Lithuania and Poland).

Bossche, V. D. (2008). Defining & Developing International Standards For Electric Vehicle Charging Infrastructures – What Are The Optimum Standards For Meeting Future Power & Charging Capabilities? American Business Conferences.

Chaouachi, A., Covrig, C. F., & Fulli, G. (2016). Framework for Electric Vehicles and Photovoltaic Synergies. JRC technical report .

Circutor. (2017). circutor.es. Available in: http:// circutor.es/es/productos/recargainteligentepara-vehiculos-electricos/recarga-exterior-devehiculoselectricos/poste-recarga-exterior-2- tomas-rve2-pt3-detail

Cobb, J. (2017). Top 10 Plug-in vehicle adopting countries of 2016. Available in: http://www.hybridcars.com/ top-10-plug-in-vehicle-adopting-countries-of-2016/

Comisión Nacional de los Mercados y la Competencia. (15 de abril de 2015). Informe sobre la propuesta de planificación de la red de transporte de energía eléctrica 2015-2020.

Concheso Alvarez, A. Nuevos ánodos de carbón para baterías de ion-litio. Departamento de Ciencia de los materiales. Universidad de Oviedo.

COTEVOS. (2017). Business Opportunities for Interoperability Assessment of EV Integration.

Department of Energy, U. S. (2016). Developing Infrastructure to Charge Plug-In.

Electric Vehicles. Available in: https://www.afdc.energy. gov/fuels/electricity_infrastructure.html

Electromaps.com. (2017). Electromaps. Available in: www.electromaps.com

Elektromobilität, S. (2017). The Showcase Regions for Electric Mobility. Available in: http://schaufensterelektromobilitaet. org/en/content/ueber_das_programm/ foerderung_schaufensterprogramm/ foerderung_schaufensterprogramm_1. html

ELMO. (2017). ELMO.ee. Available in: http://elmo. ee/estonia-becomes-the-first-in-theworld-toopen-a-nationwide-ev-fast-charging-network/

EURELECTRIC. (2016). Charging infrastructure for electric vehicles.

European Comission, & US Department of Energy. (s.f.). Harmonization of standards, technology and testing. EV-Smart Grid Interoperability Centers in Europe and the U.S.

European Distribution System Operators (EDSO). (s.f.). Position paper on Electric Vehicles Charging Infrastucture.

Fonseca Jaime Hamel. Celdas, pilas y baterías de litio. Journal boliviano de ciencias. Volumen 8 ISSN 2075-8936.

Gómez, J., & Morcos, M. (2003). Impact of EV Battery Chargers on the Power Quality of Distribution Systems. IEEE Trans. on Power Delivery, 18(3), 975-981.

Gómez, T., Momber, I., Rivier, M., & Sánchez, Á. (2011). Regulatory framework and business models for charging plug-in vehicles: infrastructure, agent and commercial relationships. Energy Policy, 39(10), 6360-6375.

Gómez Sosa, G. Algunas aplicaciones de las reacciones redox. Facultad de Química. Unam.

Grantham Institute. (2017). Expect the unexpected. The Disruptive Power of Lowcarbon Technology.

Guía de movilidad eléctrica para las entidades locales, IDAE, FEMP, REE. Available in: https://drive. google.com/file/d/1O4mDVmQfVffFIwqYlStS xjGgGhDpB1Rt/view

International Energy Agency. (2016). Global EV Outlook 2016. Beyond one million electric cars.

International Energy Agency. (2017). Global EV Outlook 2017. Two millions and counting.

International Renowable Energy Agency. (2017). Electric vehicles, technology brief.

International Programme on Chemical Safety, Instituto de Seguridad e Higiene en el Trabajo, fichas internacionales de seguridad química.

Jiang, C., Torquato, R., Salles, D., & Xu, W. (2014). Method to Assess the Power-Quality Impact of Plug-in Electric Vehicles. IEEE Trans. on Power Delivery, 29(2), 958-965.

Lo Schiavo, L. (2017). Competition and regulatory aspects of electric vehicles charging: the Italian regulatory experience.

Madina, C., Zamora, I., & Zabala, E. (2016). Methodology for assessing electric vehicle charging infrastructure business models. Energy Policy, 89, 284-293.

Martin, S. (2016). Developing a Business Model for Commercial Electric Vehicle Charging Infrastructure. Master Thesis.

Matas Díaz, F. J. (2016). Gestión del sistema eléctrico de un monoplaza. Sevilla.

Montoya, F., Martínez-Lao, J., Torres-Moreno, J., Manzano-Agugliaro, F., & Barón, V. (2016). Analysis of charging stations for electric vehicles in Spain. ICREPQ, (págs. 494-499). Madrid.

Nieuwenhuis, J. (2015). E-mobility in the Netherlands.

Peças Lopes, J., Soares, F., & Rocha Almeida, P. (2009). Identifying Management Procedures to Deal with Connection of Electric Vehicles in the Grid. IEEE Power Tech Conference. Bucharest.

PlugShare. (2017). PlugShare. Available in: https:// www.plugshare.com/

RENAULT Academy. Cuaderno del cursillista, formación carrocería, Renault Fluence Z.E.

RENAULT Academy. Cuaderno del cursillista, formación carrocería, Renault Kangoo.

RENAULT Academy. Cuaderno del cursillista, formación carrocería, Renault Twizy.

Reuters.com. (2013). Germany ends tax disadvantage for corporate electric cars.

Available in: http://www.reuters.com/article/germanyelectricvehicles-taxidUSL5N0EJ1Y320130607

Sahuquillo, M. (30-V-2017). How Estonia persuaded drivers to go electric. El País.

Sbordone, D., Bertini, I., Di Pietra, B., Falvo, M., Genovese, A., & Martirano, L. (March 2015). EV fast charging stations and energy storage technologies: A real implementation in the smart micro grid paradigm. Electric Power Systems Research, 96-108.

Searle, S., Lutsey, N., & Lingzhi, J. (2014). Evaluation of State-level. U.S. electric vehicle incentive.

Shengyin, L., Yongxi, H., & Mason, S. (2016). A multiperiod optimization model for the deployment of public electric vehicle charging stations on network. ELSEVIER, Transportation Research Part C(65), 128-143.

Sierzchula, W., Bakker, S., Maat, K., & van Wee, B. (2014). The influence of financial incentives and other socioeconomic factors on electric vehicle adoption.

Elsevier, Energy Policy(68), 183-194.

Terra, F. (2017). Los contaminantes atmosféricos: las partículas en suspensión (PM). Available in: http://www.terra.org/categorias/articulos/loscontaminantesatmosfericos-las-particulas-ensuspension-pm.

Tesla. (2016). Available in: www.tesla.com/es_ES/ supercharger.

THEMA, C. g. (2015). Mapping of TSO and DSO roles and responsibilities related to information exchange.

USCS, T. U. (2017). Market brief – E-Mobility in France (2016).

Van den Oosterkamp, P., Koutstaal, P., van der Welle, A., de Joode, J., Lenstra, J., van Hussen, K., & Haffner, R. (2014). The role of DSO in a Smart Grid environment.

Veldman, E., & Verzijlbergh, R. (2015). Distribution Grid Impacts of Smart Electric Vehicle Charging From Different Perspectives. IEEE Trans. on Smart Grid, 6(1), 333-342.

Viera Pérez, Juan Carlos. Carga rápida de baterías Ni-Cd y Ni-MH de media y gran capacidad. Departamento de Ingeniería Eléctrica. Universidad de Oviedo.

Safety

EC 61140. Protection against electric shock. Common aspects for installation and equipment.

IEC 60529 – Amendment 2. Degrees of protection provided by enclosures (IP Code).

IEC 60364-7-722. Low-voltage electrical installations: o Part 7-722: Requirements for special installations or locations –Supplies for electric vehicles.

ISO 6469-3. Electrically propelled road vehicles – Safety specifications: o Part 3: Protection of persons against electric shock.

ISO/FDIS 17409. Electrically propelled road vehicles – Connection to an external electric power supply – Safety requirements.

Gratefulness

We thank all the participants in this article, as well as other colleagues in the sector for their help and support.