Educational Project DYOR: Do Your Own Robot

Proyecto educativo DYOR: Do Your Own Robot

Leopoldo Armesto Ángel1 and Eugenio Ivorra Martínez9

Abstract

3D printers have become very popular, extensively promoting the maker movement. The educational project DYOR (Do Your Own Robot) has been created to answer the need for high-quality educational robotic resources, providing many resources free of charge so those interested in robotics can learn this discipline. This project includes a MOOC course that more than 35,000 people have taken so far.

Keywords: Mobile robots; printbot; MOOCs; 3D print; makers; electronics.

Resumen

En la actualidad, se han hecho muy populares las impresoras 3D, lo que ha impulsado mucho el movimiento maker. Aprovechando esta tendencia, se ha creado el proyecto educativo DYOR (Do Your Own Robot), que proporciona de forma gratuita muchos recursos educativos de gran calidad para que los interesados en robótica puedan aprender esta disciplina. Este proyecto incluye un curso MOOC que ha sido realizado por más de 35.000 personas.

Palabras clave: Robótica móvil; printbot; MOOC; impresión 3D; fabricación digital; electrónica.

Recibido / received: 07/06/2022. Aceptado / accepted: 14/10/2022.

1Institute of Design for Manufacturing and Production, Universitat Politècnica de València; e-mail: leoaran@upvnet.upv.es

2 Institute for Research in Human-centered Technology, Universitat Politècnica de València.; e-mail: euivmar@upvnet.upv.es

Introduction and objectives

The culture of Open Source or free software, which allows the global exchange of information, has spread to new areas in the last decade. The so-called Open Hardware (Davidson, 2004) consists of free access to construction plans of physical objects to be reproduced and improved. One of the main success stories in the microcontroller electronics field is Arduino system (Arduino-Home), which allows simple and cheap development projects that require interaction with the physical environment. In this field we also find RepRar project (Sells et al., 2010), whose objective is to create machines capable of replicating themselves and it has significantly contributed to the use of desktop 3D printers. This phenomenon, together with the democratisation of other digital manufacturing technologies (3D printing, laser cutting, CNC, and so on), has been named by several authors «the third industrial» (The Economist, 2012).

One of the consequences of digital manufacturing is that the robotic community has the opportunity to reach a wider audience. In this sense, 3D printing is an important technology in the field of robotics (Sanabria Peña, 2018). It is a relatively simple and easy process of downloading printable robot models, known as printbots, that can be used in research and for numerous academic activities (Armesto et al., 2014). These robots are more than just toys and can be used in multiple ways as educational tools for engineering and pre-engineering studies. They can be incorporated into conventional robotics courses and into all kinds of academic projects. Also, printbots allow generating ambitious projects that can be carried out by groups of students who, duly coordinated, can work in a complementary way on different multidisciplinary activities. This document will explain the printbot DYOR project (Do Your Own Robot), the associated MOOC course and the particular use case of the mobile robotics subject taught in the automation and industrial electronics degree at the Technical School of Design of the Universitat Politècnica de València (UPV). It is an optional subject in the third year that is part of the mention of robotics of the degree with 6 credits (3 classroom theory and three laboratory practices) with 30 places for students.

The primary objective of the DYOR project is to provide a low-cost educational package for robotics with great attractiveness and possibilities that can be used in different levels of education. The specific goals are:

· Democratising access to a reliable printbot for teaching robotics.

· Increasing motivation and involvement with robotics.

· Facilitating mobile robotics teaching.

These objectives are directly related to the following Sustainable Developments Goals. First, SDG 4: Quality Education by providing a series of carefully developed and detailed educational resources free of charge. And second, SDG 10: reduce inequality within and among countries since it allows people with economic resources to manufacture their own robots at a significantly reduced price and to enter the world of robotics.

METHODOLOGY

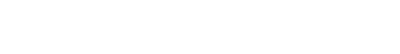

DYOR is an educational package, more than just a robotics kit. This project was born at the UPV in 2016 to be implanted as activities within the Secondary School curriculum, training professionals, robotics workshops and at the university level, but also for self-taught people to perform their own robots and learn the basics of engineering.

Associated with DYOR, the MOOC (Massive Open Online Course) course entitled “DYOR: Design, manufacture and program your own robot” (https://www.edx.org/course/ disena-fabrica-y-programa-tu-propio-robot) to extend this educational package to all possible interested people. It is, probably, a different course from many other courses that you can perform, as it does not focus exclusively on one tool or technology, but instead provides the foundation for a set of tools that will enable achieve the objectives of the course: you design, manufacture, assemble and program your own robot from scratch. Students learn to use CAD tools (TinkerCAD), design electronics (Fritzing) and Arduino block programming (Facilino) and Android apps (APP Inventor v2). The current course is in Spanish, but it is planned to have the equivalent version in English soon.

The MOOC course is made up of the topics of the following units:

· Unit 1: Introduction.

· Unit 2: CAD Design.

· Unit 3: Digital Manufacturing.

· Unit 4: Electronics and Assembly.

· Unit 5: Programming and robotics.

Tinkercad.

In addition to the university level, the course is suitable for teachers from centres of diverse educational levels, each one adapting it to their characteristics. In Spain, high education institutes, some job training specialities, and robotics associations workshops for children, youth or adults can perfectly integrate within their curricula, adapting each one to their own objectives since it requires very little prior knowledge and employs free and easy-to-use software tools.

The company Robotica Facil (Robotica Facil, 2022) has ready-to-assemble robot kits and a training web portal to facilitate the possible demand for the material needed for DYOR project. Still, the essential material is readily available in many worldwide shops. The cost of the robot’s materials is around 65 €.

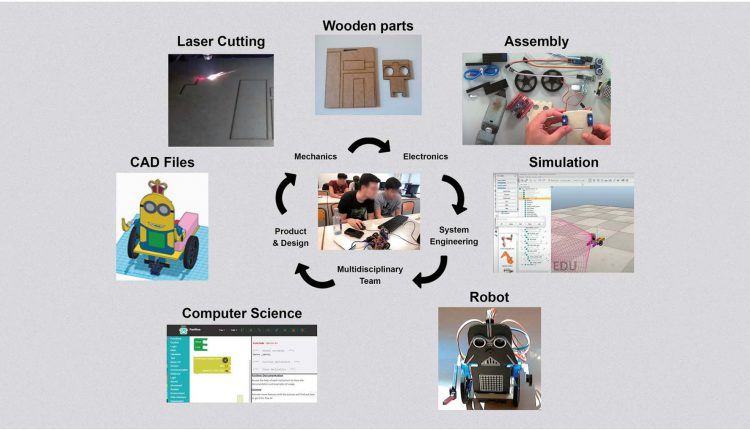

Figure 1 shows the CAD design of the DYOR robot made in Tinkercad in its standard version.

The components of this robot are the following:

• Arduino Nano + Shield Arduino Nano I/O (red).

• Power bank (yellow).

• Ultrasound HC-SR04 (light grey).

• Sound buzzer (black).

• SG90 servos (blue) on the base.

• Engines SmartCar (yellow).

• Wheel SmartCar (yellow/black).

• Driver DRV8833 (black).

• Bluetooth (grey).

• TCRT5000 Line Tracker (blue dark).

• Idler wheel (white).

• LED matrix (green).

• LEGO pieces (purple).

With DYOR robot, you can implement many activities, control basic movements, open/close the tweezers to manipulate objects, follow lines, avoid obstacles, get out of mazes and even remotely control the robot from a mobile device.

In the particular case of the university environment, it is possible to delve further by modifying the standard design and adding different sensors and actuators, as we will see in the results section. In addition, more advanced robotics concepts, such as kinematic modelling, can be explained in this context. For differential steering mobile robots such as DYOR, the main purpose of kinematic modelling is to represent the robot’s speed as a function of the wheels’ speeds using the robot’s geometric parameters.

modifications).

Results

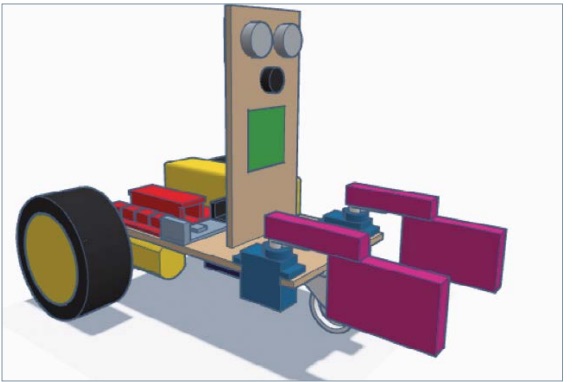

Figure 2 shows a set of robots designed by UPV students in 2017 during the Mobile Robotics subject that is Figure 1. Standard DYOR robot version made in Tinkercad. taught at the ETSID. As can be seen in the figure, the students, although they had the opportunity only to design the standard version, were very motivated and involved and significantly modified the basic design. These modifications included adding different sensors, actuators, chassis and even changing the wheel configuration. The DYOR project gives them a solid foundation on which to work and total freedom to develop their creativity, thus enhancing learning.

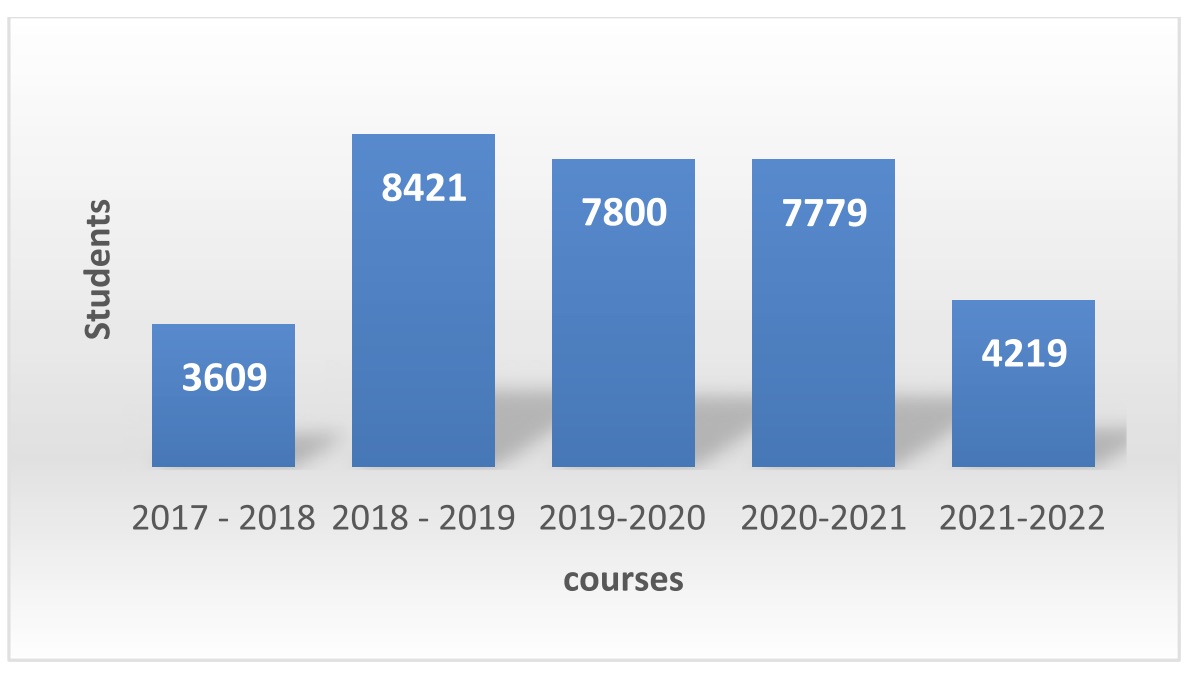

The MOOC course linked to DYOR has had great success with many students, as shown in the graph in figure 3. In 2017 the number was lower for two reasons: it is the year the course was launched, and it started in the middle of the year. In 2021-2022 there is also a decrease in students because it is the current academic year (it is counted until September).

Conclusions

More than 30,500 students have completed the DYOR project through the free MOOC course available on EDX. Furthermore, it has been shown that it is possible to effectively employ it at the university level in a subject in an official degree. The possibilities offered in this educational package motivate the students to perform much more advanced and complex robotics assignments than those required in the subject. Also, there is a roadmap to translate the course into English to reach a wider audience and better fulfil the SDGs of guaranteeing quality education and reducing existing inequalities in access to robotics by people with limited economic resources who speak English.

Thanks

We thank the support in manufacturing and materials provided by the Higher Technical School of Design Engineering of the UPV, without which this project would not be possible.

ReferencesArduino-Home. (s.f.). Retrieved May 9, 2022, from https://www.arduino.cc/

Armesto, L., Conejero, A., Fernández, M., Fuentes, P., Perry, D., Bert? , E., Marhuenda , V., Igual, C., de la Fuente, C., & Elesgaray , O. (2014). Printbots : A big step towards forward. Automatic Conference XIV.

Davidson, S. (2004). Open-source hardware. IEEE design & test of computers, 21 (5), 456-456.

Sanabria Pena, OH (2018). Analysis of the relationship between the Maker movement and technology education. A look at the seedbed “ Robotics and 3D Printing “ of the ETITC.

Sells, E., Bailard, S., Smith, Z., Bowyer, A., & Olliver, V. (2010). RepRap: The replicating rapid prototyper: Maximising customisation by breeding the means of production. In Handbook of Research in Mass Customization and Personalisation: (In 2 Volumes) (pp. 568-580). World Scientific.

The Economist. (2012). The third industrial revolution. The Economist. https://www.economist.com/ node/21553017.

Robótica Fácil, Accessed October 11th, 2022, website https://roboticafacil.es